There is a possibility that many horses will make variable degrees of contact between the teeth and the bit. When this happens we would like to ensure that the impact forces are safely and comfortably absorbed into the material of the bit rather than the teeth. Not only is this a better experience for the horse but it will reduce tooth wear that can occur with prolonged contact with a hard bit. The material has to be softer than enamel for this and in fact all modern bits use materials with hardness values lower than that of tooth enamel. But again we have a spectrum of values.

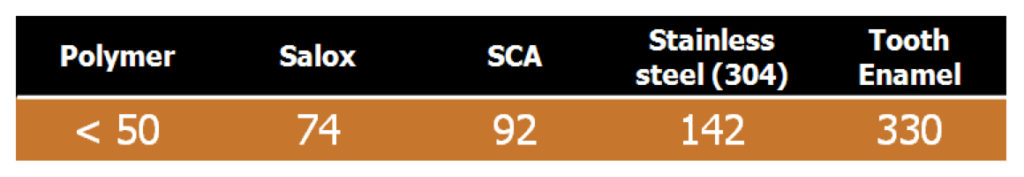

Table 2: Hardness values (Vickers 10kgf scale) measured (Stainless steel, SCA and Salox) or taken from literature sources for tooth enamel2 and polymer3

Polymer bits lie at the most yielding end of this spectrum and absorb the impact by either elastic deformation (low tooth pressure) or varying degrees of permanent ‘damage’ (moderate to high pressure) usually by forming small cuts in the surface (exceeding the so-called “tearing” force for the polymer). This property is comfortable for the horse and safe, provided there is not too much removal of material, which needs to be monitored carefully when using these products.

At the top end of the hardness spectrum, stainless steel is quite unyielding and will provide a significant elastic reaction force against the tooth, perhaps best described as ‘jarring’.

So, in Salox we make sure that there is a way for the force to dissipate into permanent deformations (depressions or ‘dents’) in the surface. Unlike polymer bits, repeated contact with the teeth removes little or no material and in fact leads to a slightly more resistant surface over time due to strain hardening. We therefore make Salox strong and extremely tough, but to take advantage of the favourable features of polymer, somewhat softer than all current bit metals.

So far then, we can say that Salox is ‘warmer’ and ‘softer’ than all other bit materials, except for polymers.